| Model | TMT-J12 | TMT-J18 | TMT-J40 | TMT-05 Pro (skid-mounted) | TMT-10 | TMT-30 | TMT-50 |

| Input Capacity | 12m³/batch | 18m³/batch | 40m³/batch | 0.3-0.5m³/h | 2-4m³/h | 7-9m³/h | 10-15m³/h |

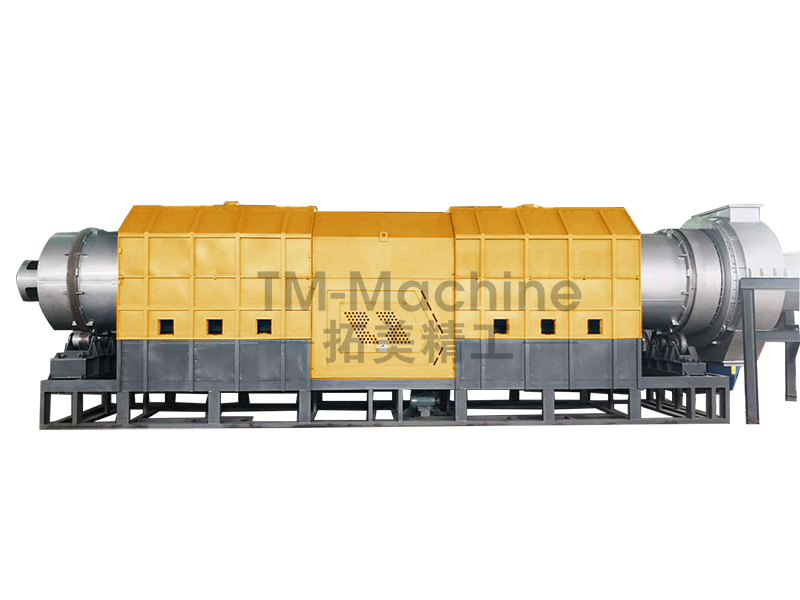

| Reactor Size | φ1900mm * L4500mm | φ1900mm * L6600mm | φ2800mm * L7100mm | φ830mm * L5500mm | φ1300mm * L14051mm | φ1700mm * L14180mm | φ2000mm * L14260mm |

| Land for Equipment (L*W*H, Standard Configuration) | 9m*6m*6m | 12m*6m*7m | 15m*18m*7m | 10m*8m*3.9m | 29m*15m*5m | 30m*15m*8m | 35m*18m*9m |

| Weight (Standard Configuration) | 18T | 22T | 34T | 15T | 35T | 35T | 49T |

| Energy Consumption (Standard Configuration) | 11kw/h | 13.5kw/h | 25kw/h | 31kw/h | 34.7kw/h | 61.5kw/h | 116kw/h |

| Working Method | Batch | Fully continuous | |||||

| Feeding Requirement | / | Size: ≤20mm; moisture: ≤15%; strong liquidity | |||||

| Structure | Horizontal rotation | Double barrel single hearth | Double barrel double hearth | ||||

| Speed | 0-2RPM | 1-9RPM | |||||

| Control Method | Control by buttons | Automatic control | |||||

| Reactor Material | Q245R | Q245+310S | |||||

| Pressure | Micro negative pressure | ||||||

| Heating Material | Diesel, natural gas, heavy oil, biomass, etc. | ||||||

| Heating Method | Direct heating | ||||||

| Noise (dB) | ≤80 | ||||||

| Condenser | Circulating water cooling | ||||||

| Rotation Method | External gear rotation | ||||||

| Return on Investment of TMT-50 Wood Chips Carbonization Project in The Middle East Regin | ||||||||

| Item | Details | Unit | Unit price/USD | Quantity | Amount/USD | Total amount | Remark | |

| Fixed Investment Cost | Equipment | TMT-50 | Set | 250000 | 1 | 250000 | ||

| Transportation | From China to Destination Port | Set | 90000 | 1 | 90000 | |||

| From Port to Site | Set | 5800 | 1 | 5800 | ||||

| Customs tax | 0.15 | Set | 37500 | 1 | 37500 | |||

| Installation | TM-Machine technician's salary | Day | 100 | 50 | 5000 | |||

| Round -trip airtickets | Ea | 2420 | 2 | 4840 | ||||

| Visa | Ea | 350 | 1 | 350 | ||||

| Local welder | Day | 65 | 100 | 6500 | Two welders are needed | |||

| Local plumber | Day | 65 | 20 | 1300 | ||||

| Local labor | Day | 16.8 | 50 | 840 | ||||

| Crane forklift etc. | Day | 80 | 30 | 2400 | ||||

| Materials | Installation materials ready | Set | 3500 | 1 | 3500 | Foundation, pipe, etc. | ||

| License | / | Ea | 2000 | 1 | 2000 | Environmental, firefighting, etc. | ||

| Workshop | 500 | ㎡ | 160 | 500 | 80000 | |||

| 490030 | ||||||||

| Operating Cost | Raw materials | Wood chips | Ton | 100 | 120 | 12000 | ||

| Water | / | m³ | 1.76 | 3 | 5.28 | |||

| Electricity | / | KWH | 0.11 | 2922 | 321.42 | |||

| Fuel | Natural gas | Liter | 7.25 | 270 | 1957.5 | |||

| Labor | / | People | 16.8 | 4 | 67.2 | |||

| Maintenance | / | Day | 85 | 1 | 85 | |||

| Depreciation | 8 years | Day | 209.3 | 1 | 209.3 | |||

| Tax | 0.05 | 0 | ||||||

| 14645.7 | ||||||||

| End Products Price | Biochar | 0.3 | Ton | 680 | 36 | 24480 | 30% of input | |

| Wood vinegar | 0.08 | Ton | 1280 | 9.6 | 12288 | 8% of input | ||

| Tar oil | 0.02 | Ton | 450 | 2.4 | 1080 | 2% of input | ||

| 37848 | ||||||||

| Daily Income | 23202.3 | |||||||

| Monthly Income | Working day | Day | 25 | 580057.5 | ||||

| Yearly Income | Working day | Day | 300 | 6960690 | ||||