| Products | Usage |

| Pyrolysis oil | • Pyrolysis oil can be sold to industries directly. |

| • Non-standard pyrolysis oil is reprocessed into high-quality oil by waste oil distillation machine. | |

| • Oil can be used as fuel for iron factory, power plant, cement factory, ceramic factory, restaurant, etc. | |

| Carbon black | • Carbon black can be sold directly. |

| • It can be reprocessed into high-quality carbon by the carbon black processing plant. | |

| • It is used to make carbon brick by briquetting equipment. | |

| Steel wire | • Steel wire can be sold directly. |

| Combustible gas | • It can be used as fuel heating the reactor. |

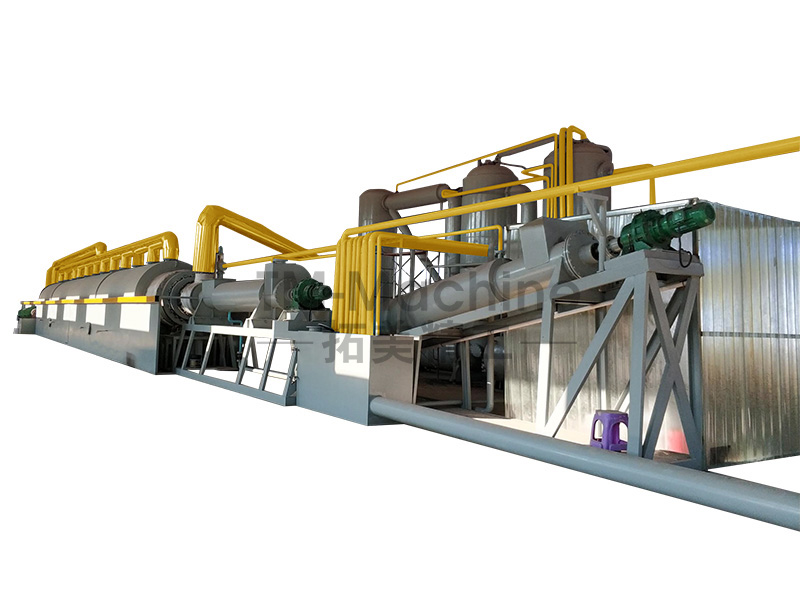

| Model | TMF-20 | TMF-30 | TMF-50 |

| Capacity | 20 t/d | 30 t/d | 50 t/d |

| Working Process | continuous | continuous | continuous |

| Reactor Size | Φ 1200 * 9450 mm | Φ 1500 * 13000 mm | Φ 2000 * 15200 mm |

| Reactor Material | 310S | 310S | 310S |

| Drive System | ZSY160 reducer + 5 . 5 kw drive motor | ZSY180 reducer + 7 . 5 kw drive motor | ZSY200 reducer + 1 5 kw drive motor |

| Land ( L * W * H ) | 45 m * 20 m * 10 m | 50 m * 25 m * 10 m | 55 m * 30 m * 10 m |

| Burner | 4 * 250,000 kcal | 4 * 350,000 kcal | 3 * 600,000 kcal |

| Noise (dB) | ≤60 | ≤60 | ≤60 |

| Heating Materials | Fuel oil ( including tyre/plastic pyrolysis oil ), natural gas, LPG, diesel, etc. | ||